Home > Vayufil > Conventional Dust Collector filter bags

Conventional Dust Collector Filter Bags

By GSE

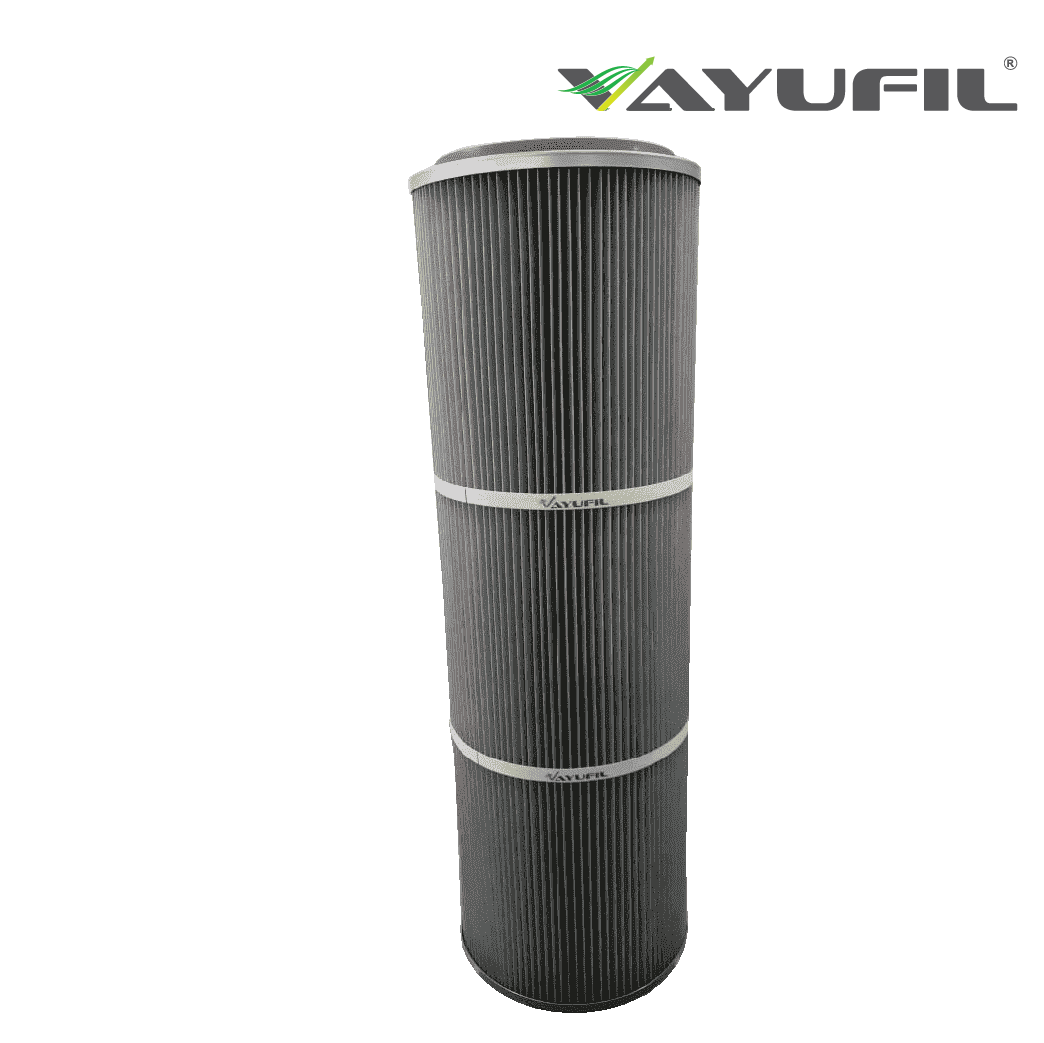

The Dust Collector Filter Bag is the most important component of an Industrial Bag House. These bags form the permeable filtration barrier that arrests the unwanted dust particles and allows the clean air to pass through it. These bags are suspended from the “tube sheet” or the “mounting plate” of the bag house which separates the dusty side from the clean side. These bags are made using different industrial textiles, which have to be carefully selected to suit the application. These industrial textiles are ‘nonwoven needlefelt’ material manufactured on a needle-loom. They provide an optimum permeability suited for low emissions, while working on depth filtration technology. The following aspects of the bag play a direct role in the overall emission efficiency of the bag house and life of the bag - Dimensional Accuracy of the Bag, Stitching Quality and Sewing Thread, Use of correct textile (media) for a particular application, Quality of the textile itself (surface finish/air permeability/tensile strength, etc). The VAYUFIL range of filter bags from GSE fulfils the above criteria and promises an effective solution to its customers.

Specifications

| Media | Temperature | Acid Resistance | Alkali Resistance | Hydrolysis Resistance | Remarks | Applications |

| Polyester | Cont: 140° C Peak: 150° C | Good | Fair | Fair | Dry conditions upto 150° C. High Alkaline content is a problem | Cement, Iron & Steel, Pigments, Shot Blasting, Powder Coating, Asbestos, Wood, Plastics, Rock Crushing etc |

| Polypropylene | Cont: 90° C Peak: 100° C | Excellent | Excellent | Excellent | Moist Conditions upto 90° C. Hygroscopic dusts at low temperature with increased chemical attack | Detergents, Fodder, Milk Powder, Fertilizers, Sugar, Flour, Chemical Industry |

| Acrylic(Homopolymer) | Cont: 130° C Peak: 140° C | Good | Good | Excellent | Moist Conditions upto 130° C. Used an alternative to Polyester for better resistance to alkaline and hydrolysis | Aphalt Mixing, Gypsum, Spray Dryers, Cement, Lime, paint |

| Mixed Felt | Cont: 140° C Peak: 150° C | Good | Fair | Good | Blend of Polyester and Acrylic for cost effectiveness. Mixed Felt has some natural antistatic properties | Aphalt Mixing, Gypsum, Spray Dryers, Cement, Lime, paint |

| PPS Polyphenylsulphide(Ryton) | Cont: 180° C Peak: 190° C | Excellent | Excellent | Excellent | Applications with gas temperatures upto 180deg C with increased chemical attack | Coal Fired boilers, Chemical Industry, Gypsum |

| Aramid (Nomex) | Cont: 200° C Peak: 220° C | Fair | Good | Fair | Dry & Hot conditions, above dew point upto 200° C | Iron Smelters, Ashpalt Mixing Plants, Wood Fired Boilers, Ceramics, Lime |

| Polyimide P84 | Cont: 250° C Peak: 260° C | Good | Fair | Fair | Dry & Hot Conditions, above dew point upto 250° C. The unique multilobar fibre structure provides for low emissions | Waste Incinerators, Cement Kilns, Chemical Industry, Coal Fired Boilers |

| Polytetrafluorethylene PTFE (Teflon) | Cont: 260° C Peak: 280° C | Excellent | Excellent | Excellent | Hot Conditions upto 260° C with increased chemical attack. Very strong material and withstands a high surge temperature | Coal & Oil Fired Boilers, Calciners, Incinerators, Smelters |

| Woven Glass Fibre | Cont: 260° C Peak: 290° C | Good | Fair | Fair | Hot conditions upto 260° C. Used as a cost-effective alternative to PTFE | Coal & Oil Fired Boilers, Cement Kilns, Incinerators, Ceramics etc. |

Coatings Available : Oil & Water Repellent Coating/PTFE Membrane Lamination / Antistatic Coating

Bag Desings : Snap Band/Felt Snap Band/Collar/Ring/Cassette Type/Custom Designs

Air Filtration Products

Want to know more?